Plastic alloy pipe for communication

The plastic alloy pipe used a variety of polymer materials and it is made after interpenetrating network alloying technology. It has excellent acid, alkali, salt and other chemical corrosion resistance, the service life is at least 30 years and buried for 50 years. It also has high toughness, high pressure resistance and high impact resistance. The special fixation is not needed in the construction. When doing the connection, you just need to set in after the special glue. It can be applied to all kinds of infrastructure of communication cables and power cables instead of steel pipe across the road.

Product feature:

1. Good corrosion resistance and environmental adaptability

It has excellent acid, alkali, salt and other chemical corrosion resistance. Tested by Zhejiang Technical Supervision Bureau, its index (≤1.50g/square meter) meets the technical requirements of corrosive fluid transmission pipe. So it is suitable for all kinds of soil and working environment. For example, the service life of the steel pipe is only 3~5 years laid in saline-alkali land, however, the plastic alloy pipe is at least 30 years, if it is buried, the service life can reach 5 0 years.

0 years.

2. Novel structure, high compressive strength:

It uses the multi-alloying technology of interpenetrating network and takes the advantage of principle of mechanical distribution to design the innovative structure. It adopts a unique enhanced integral mechanical frame with square outside and regular dodecagon inside and auxiliary triangle support to disperse the stress to support the pipe and improve the compressive strength. So it has the outstanding performance of high toughness, high pressure resistance and high strength. Structure, formula and technology are the three major innovations of this product.

3. Wide application:

It can be widely used in all kinds of infrastructure of communication cables and power cables instead of steel pipe across the road and also other occasions with special requirements for pipeline protection to make the pipeline operation more reliable and safer.

4. Assembly of the pipe parts is convenient:

The innovative structure of the pipe not only achieves the purpose of dispersing stress support and improving compressive strength, but also facilitates the assembly of the pipe parts. The special fixation is not needed in the construction.

5. Convenient construction and low project cost:

The pipe is connected by bushing and only need to be coated with special glue when being connected. The end of the pipe is printed with an assembly mark, which is convenient for supervision personnel to check whether it is set to the position. Compared with steel pipe, it reduces labor intensity during construction. The price of the pipe is only 2/3 of that of steel pipe. Only from the material cost of a calculation, the engineering cost of each kilometer can save nearly 20,000 yuan, and the service life is much more than steel pipe.

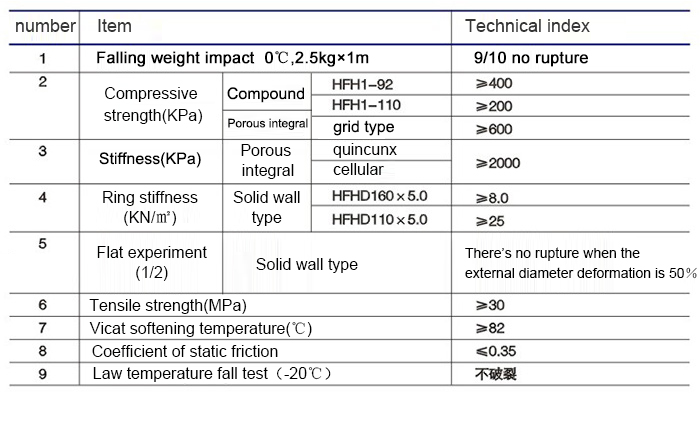

Mechanical Properties of plastic alloy pipe for communication

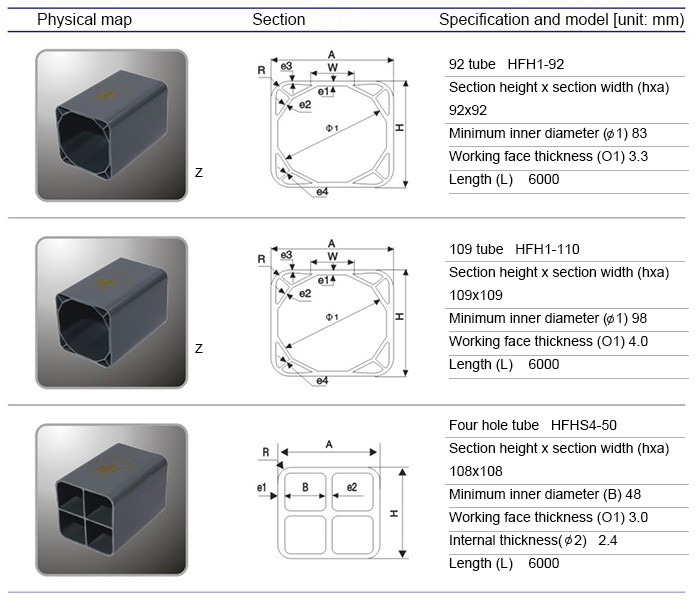

Standard specification for plastic alloy pipe for telecommunication

“Feng”communication plastic alloy pipe, can be widely used in all kinds of communication cables, optical communication cables and power cables and other engineering infrastructure to replace the steel pipe crossing the road, and other special requirements on pipeline protection occasions.